Gearless machine;

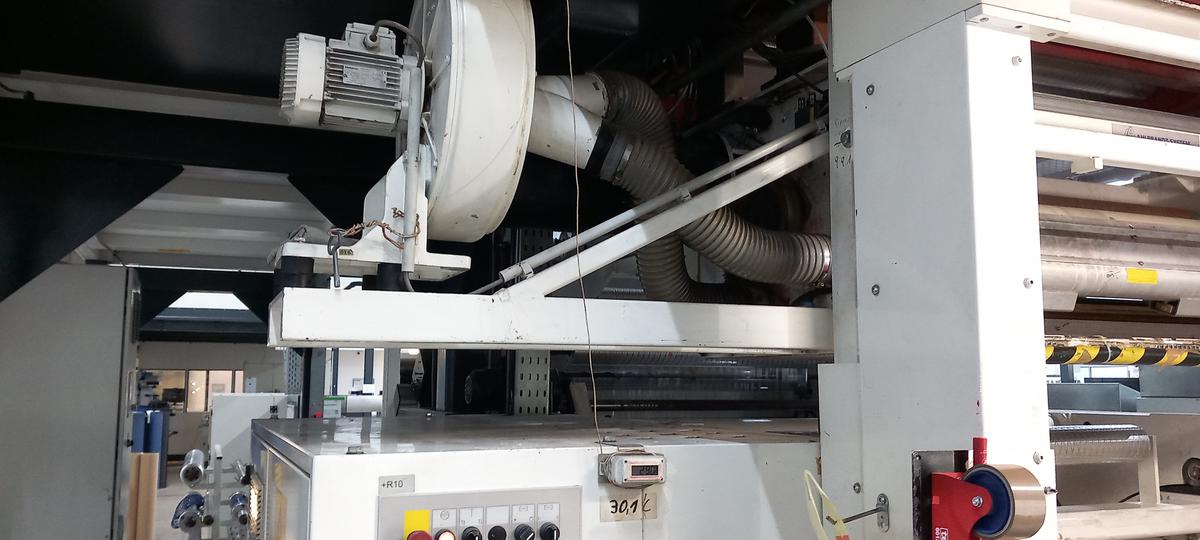

Automatic washing system Turboclean 400;

Web video inspection system BST Genius combined with 100% inspection AVT PrintVision-Apollo;

Two-zone drying system with heat exchanger for hot water (temperature: 105 °C);

Corona treatment AHLBRANDT System 6 kW;

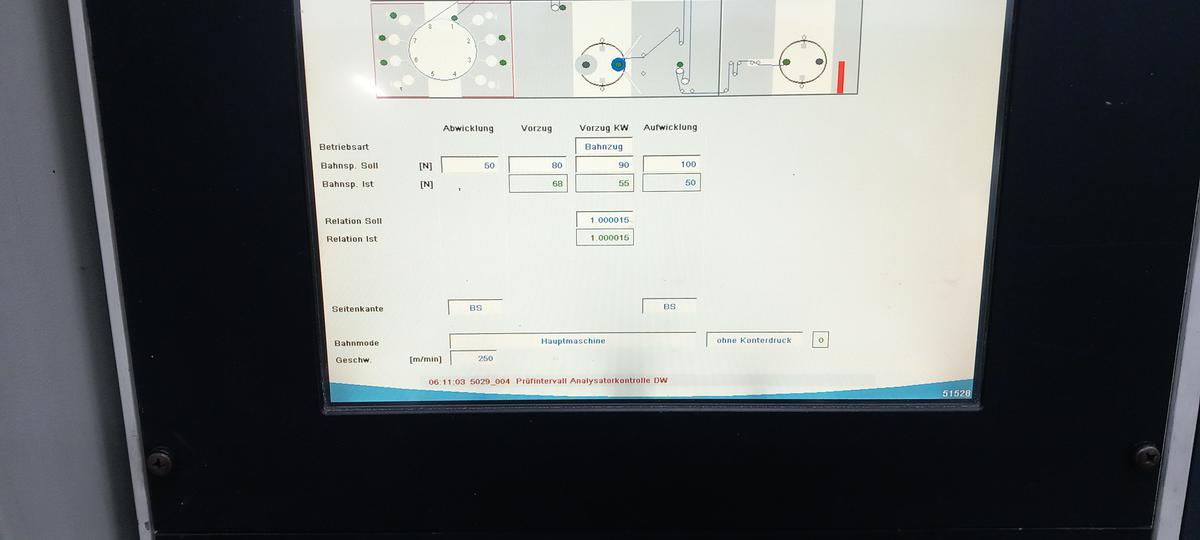

2 x web guide system BST EKR 1000;

Viscosity control system;

Machine is prepared for solvent based inks;

Materials to be printed:

LDPE, PP: 20 -150 µ;

HDPE OPP: 12-100 µ;

Laminates: up to 150 µ;

Paper: 30 -120 my;

PET, OPA, BOPP: 10 µ -30 µ;